Four major installation considerations for HDPE Pipe:

1. Outdoor installation, if there is sunshine, you can take measures.

2. HDPE pipe installation, if the operation space is too small, the connection mode should adopt the fusion type.

3, the heating temperature of the hot-melt socket connection is not too high, too long, the best temperature control 210 ± 10 ° C, otherwise it will lead to excessive extrusion of the magma parts, reduce the water diameter; Socket pipe or pipe joints should be clean otherwise, it will cause the socket to close and leak; at the same time, pay attention to controlling the angle and direction of the pipe to avoid rework.

4. The voltage required for hot-melt butt connection is 200 ~ 220 v. If the voltage is too high, the temperature of the heating plate will be too high, the voltage is too low, the docking machine will not work, and the interface should be aligned. Otherwise, the interface area will be required. Insufficient, joint strength, the edge are wrong; When the heating plate heat pipe joint is not clean enough or the heating plate has oil, sludge and other impurities, resulting in interface separation leakage; Heating time control, heating time is short, tube heat does not have enough time Will cause the joint edges to be too small, the heating time will be too long, causing the joint edges to be too large and may form a virtual weld.

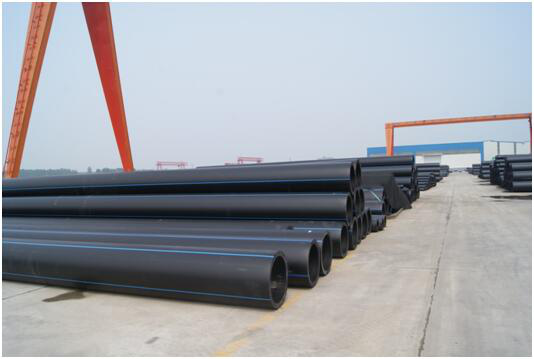

We can provide you with a variety of HDPE Trenchless Pipe. If you are interested in our products, you can contact our class or visit our company.